Rotary Wire Braider - Model: ROBiT

DOWNLOAD LEAFLET

24 Carrier Single Deck Rotary Wire Braider

Penguin Orbital Braiders, ROBiT is Engineered and Precision built to deliver reliable performance for High speed braiding of hydraulic hoses, Cables and similar material that are to be braided with high precision. The rotary path of the carriers enable high speed operation and reliability.

The contra rotating sets of carriers carry wire bobbins with precision tensioning mechanism. The strands from the outer carriers are displaced by suitable linkage mechanism. This eliminates wear of machine components. The braids formed are compacted to ensure a compact lay of braid on the hose.

Specifications

| Number of carriers | 16 | 20 | 24 | |

| Carrier speed (rpm) | Wire | 90 | 80 | 70 |

| Yarn | 100 | 90 | 75 | |

| Productivity | Wire | 1.6 m / min | 1.8 m / min | 3.1 m / min |

| Yarn | 1.8 m / min | 2.0 m / min | 3.4 m / min | |

| Hose ID | 8 mm | 10 mm | 12.7 mm | |

| Bobbin capacity | Wire | 13 kg / 2200 cc | ||

| Yarn | 1.75 kg / 2200 cc | |||

| Carrier tension | 2 to 13.5 kg (Adjustable) | |||

| Bobbin size | Ø 140 x 160 mm Traverse | |||

| Operator panel | Touch screen panel - HMI 7" | |||

| Local panel | Push button panel | |||

| Material | High-tensile brass-coated steel wire, Stainless steel wire, & various yarns, including Polyester, Nylon and Aramid | |||

| Power supply | 415 V / 3 phase | |||

-

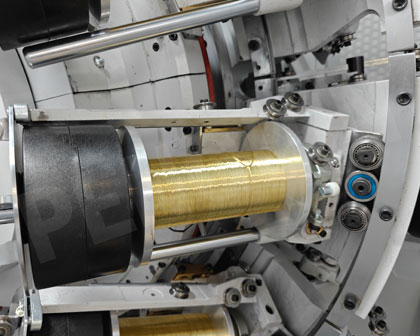

Deck with wire carriers

-

Clutch spring

-

Tension spring

-

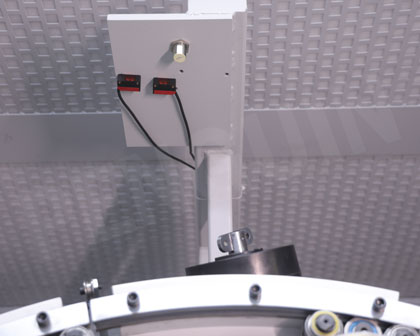

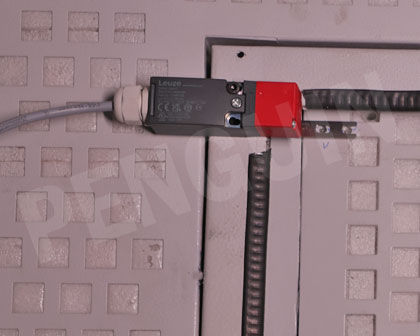

Sensor

-

Wire Bobbin

-

Haul-off

-

Outer carrier

-

Push buttons

-

Deck motor

-

HMI

-

Control panel

-

Push buttons

-

Rotary carrier

-

Exhaust fan filter

-

Door safety limit switch

-

Inner carrier

-

Manual carrier loading

-

Haul-off Entry & Exit

-

Control panel

Features of Rotary Wire Braider

- Higher Productivity: Delivers nearly three times the output of a maypole braider

- Enhanced Bobbin Capacity: Lower inertial forces enabling heavier wire bobbins

- Versatile Braiding Capability: Suitable for high-tensile brass-coated steel wire, stainless steel wire, copper and tinned copper wire

- Larger Bobbin Capacity: Accommodates increased material volume and hence suitable for textile braiding

- Servo Drive System: Ensures controlled and smooth machine startups & running.

- Low-Maintenance Design: Engineered for reliability and minimal routine maintenance.

- Streamlined Data Management: HMI (Human Machine Interface) enables easy data input, output, and standardization.

- Haul-off: With endless segmented track, vertically reversible type, suitable for hoses of 10mm to 100mm diameter.

- Haul-off Jaw opening 150mm (6”)

- Digital display for pitch, deck RPM and productivity information

- Carrier

-

Optimal rigid design

- Bobbin made of lightweight materials for increased efficiency & enhanced productivity

- Lightweight bobbins enhance productivity

- PLC / HMI Operation

- User-Friendly System: Simplified operation with advanced servo control

- Enhanced Safety & Stability: High-performance motion controller ensures reliable operation.

- Smart Monitoring: Displays machine faults and maintenance alerts.

- Customizable Measurement Units: Supports both metric and imperial systems.

- Multilingual Interface: Provides global accessibility with multiple language options.

Looking for an Adequate Solution for your Company?

Contact us today for free consultation or more information.

Contact Us© 2021 PENGUIN ENGINEERS