Hose Wrap / Unwrap System (For Rigid Mandrel Hoses)

Model: WRAPMASTER 600RC

DOWNLOAD LEAFLET

Hose Wrap / Unwrap Machine - For Rigid mandrels

Penguin Wrapmaster 600RC wraps and unwraps cured tape over rigid mandrels. The machine can wrap hoses of different diameter and use range of tape widths. The operation is completely controlled from the interactive touch screen. The machine ensures that wrapping is done with minimum variation in pitch and at controlled wrap and unwrap tension. The mechanical sub systems are the wrap head, haul-off caterpillar, brand tape feeder and doors

Specifications

| Head drive | 22 kW |

| Spool drive | 15kW |

| Caterpillar drive | 4 kW |

| Brand tape drive | 1.5 kW |

| Drives | Servo drive |

| HMI 9" | 9" Colour touch screen |

| Operation | Fully automaticwith PLC control |

| Frame | Heavy duty steel structual frame |

| Caterpillar | Positive drive belt with pressure distributing rollers |

| Compressed air | 6 kg/cm2; 30 liters / hour |

| Noise level | <75 dB |

| PRODUCTION DATA | |

|---|---|

| Mandrel system | Rigid mandrel |

| Hose / Cable length | No restriction |

| Type of hose | Wire / fabric reinforced |

| Pintle bore diameter | 140 mm |

| Output | upto 40 m / min. |

| TAPE SPOOL CAPACITY | |

| Core | Taper core with circular section |

| Storage | One operational + One storage |

| TAPE | |

| Core diameter | 308 mm |

| Maximum tape spool diameter | 750 mm |

| Tape width | 50 mm to 130 mm |

| Maximum tape length | 1500 m |

| Power consumption | <15 kW |

| Floor space | 1.6 x 3.5 m |

| Weight | 5000 kg |

-

Sliding door

The machine is provided with sliding main door. Convenient transparent window is provided on the door for the operator to monitor the progress of the operation. This stainless steel door collects the water splashing during the wrapping operation and provides for convenient drainage.

-

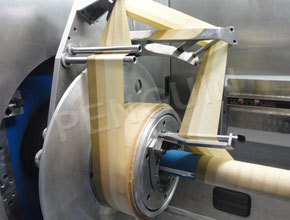

Wrapping Head

The head has shuttle plate and tape spool mounted concentrically on a hollow pintle. The tape spool is clamped with expansion pin / bolt. The machine uses one piece ring type tape core. The center height of the head is automatically varied to suit the hose diameter using electro‐hydraulic circuit with feedback.

-

Caterpillar

The caterpillar has rubber lined posive drive belts and both the top and bottom belts are power driven. The caterpillar jaws are opened and closed pneumatically. The front side of the caterpillar is provided with a transparent access window protected by safety switch with bypass arrangement. The caterpillar can be accessed for lubrication and adjustments with conveniently located side doors.

-

9" Touch screen

Wrapmaster 600RC is controlled by state‐of‐the‐art controller that communicates with the individual motor drives at high speeds. The operator controls the machine through the interactive touch screen and the push button stations provided in the machine. The machine can be brought to rapid stop in a controlled manner without variation in pitch. The spool motor is controlled in a torque controlled mode and it responds to torque value set through the operator interface.

-

Brand tape system

The Wrapmaster 600RC has a unique brand tape feeding system. The system is driven by separate servo motor with electrical drive. This ensures trouble free feeding of brand tape even at high speeds. Short time change over from wrap to unwrap mode is possible even when the brand tape system is ON.

-

Drives

The wrapping machine is driven by four electric motors viz.

- Head drive motor

- Spool drive motor

- Caterpillar drive motor &

- Brand tape drive motorThe motors are driven by precision drives and are synchronized through the dive controllers. The synchronizing between the head and caterpillar speed ensures less than ±0.1 % (one in thousands) variation in pitch during wrapping. During unwrapping, the caterpillar responds almost instantaneously to ensure that the tape is unwrapped neatly under control of laser optic sensors.

-

Control panel with AC

Features of Hose Wrap / Unwrap Machine

CLICK HERE FOR Penguin HOSE WRAP / UNWRAP SYSTEM - FLEXIBLE MANDREL HOSES

Looking for an Adequate Solution for your Company?

Contact us today for free consultation or more information.

Contact Us© 2021 PENGUIN ENGINEERS