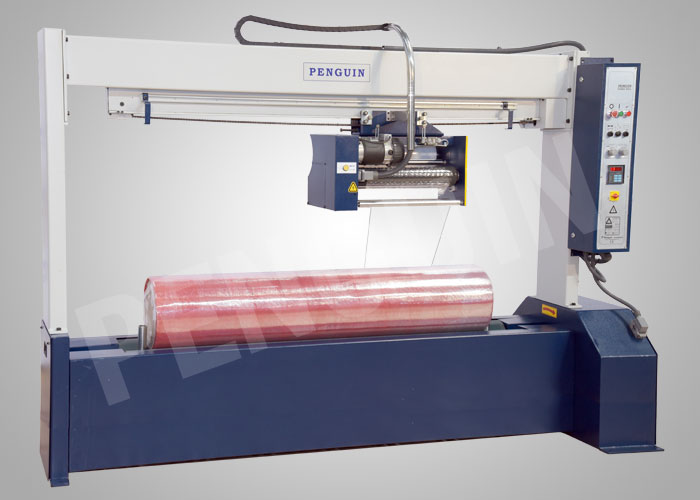

Fabric Roll Wrapping Machine

Model: FABRIC ROLL

DOWNLOAD LEAFLET

Fabric RollWrapper with DC Motor and DC Drive

Penguin fabric roll wrapping machine packing denim, carpet rolls - at Denim cloth manufacturing.

Stretch wrapping is the most economical way of Roll packing. The Penguin Fabric Roll Stretch Wrapping Machine is the prestigious “Pacmachine” award winner. It is used to pack rolls of many items like denim fabric, carpets, curtain cloth, paper, film etc.

Penguin Stretch Wrapping Machine offers the most profitable way to pack your valuable goods by saving in cost of film, labour and power. Penguin machines are from the leaders in stretch wrapping and are in use at various industries all over India and Abroad. Read more...

Specifications

| CAPACITY | |

|---|---|

| Rolls / Hour | 20 - 40 nos. |

| Weight / Roll (max.) | 400 kg |

| Weight / Roll (min.) | 20 kg |

| Roll diameter | 600 mm |

| Roll width (standard model) | 1800 mm |

| MACHINE | |

| Rubberized roll height (above GL) | 350 mm |

| Speed | 50 m / min. |

| Max.powered stretch | 300% |

| Installed power | 1.5 kW |

| Power supply | 220V, Single Phase, 50 Hz |

| FILM DETAILS | |

| Material | LLDPE Stretch film |

| Film width | 250 - 500mm |

| Film thickness - Range | 12 - 35µ |

| Film thickness - used | 23µ |

| Core diameter | 76 mm |

| Maximum film diameter | 250 mm |

- Return-on-Investments is only a few months

- Outstanding efficiency and economy of the machine won us the prestigious "Pacmachine Award"

- Saves 95% electrical energy compared to Shrink wrapper

- Modular in construction

- Powered pre-stretch upto 300% stretch

- Highly economical and huge savings over shrink packing/gunny bundles

- Suitable for packing any rolls of Denim Cloth, Curtain Cloth, Carpets, Foam sheets, Upholsteries, Fabrics, Film, Paper etc.

- Occupies less space

- Tremendous savings in labour, time and money

- Highly durable dust and moisture proof packing

- Powered Pre-Stretch unit to minimize film consumption

- Adjustable traverse to suit different roll width

- Controlled film tension

- Variable Overlap, Variable End Reinforcements, Variable Stretch Percentage and Variable Roller Speed

- Digital counters for end reinforcement wrap setting, film consumption and stretch percentage display

- Simple to operate, sturdy & safety control panel

- Cradle for easy loading of film

- Easy loading and unloading of Fabric roll and ease of integration into conveyor lines

- Minimum service points

- Payback period is only few months

- Excellent after-sales-service support

Features of the machine

Productivity: 20 - 40 Rolls / hour.

Applications:

Fabric rolls, Grey cloth, Denim rolls, Carpets, Curtain cloths, Upholsteries, Foam Sheets, Fabrics, Film, Paper, PP Rolls, etc.,

Roll width 1800mm and roll diameter 600mm or custom

-

Fabric RollWrapper with AC Motor, ACDrive and HMI for automated operation

-

Fabric rolls waiting to be stretch wrapped at Denim cloth manufacturing unit.

-

Side view of the Denim Rolls duly packed with end-caps

-

Fabric Rolls - Stretch wrapped and stored in the warehouse - dust and moisture free

-

Denim Rolls - Duly stretch wrapped and stored in denim cloth manufacturing unit

Gallery of Fabric Roll Stretch Wrapping Machine

Read more on Penguin FABRIC ROLL Stretch Wrapping machine

It is a real fact that for all those weaving industries where the production is huge, handling Cloth Rolls for local transportation or for exports, without affecting their Quality, will always be a problem, unless & until the above machine is introduced.

This machine is ideally suitable for large weaving mills manufacturing heavier and wider-width cloth rolls like Denim Fabrics, Carpets, Upholsteries, where cloth in Roll-Forms are to be protected from dust & moisture when in storage and in subsequent transportation.

The automated operation cycle can be programmed and monitored through microprocessor interface. This machine saves huge labour costs as well as packing time apart from convenience while loading trucks / containers when dispatched from mills. Changing over from Shrink wrapping to this type of Stretch Wrapping, gives huge amount of savings in power costs, and hence its cost of investment is paid back within 'few months'.

It is easy to operate & very simple to maintain; it is sturdy & user friendly; it can accommodate even wider width - bigger diameter fabric rolls & stretch wrap them quickly. This machine is using 220 V, 1-phase, 15 Amps, & 1.5 kW power supply.

Looking for an Adequate Solution for your Company?

Contact us today for free consultation or more information.

Contact Us© 2021 PENGUIN ENGINEERS