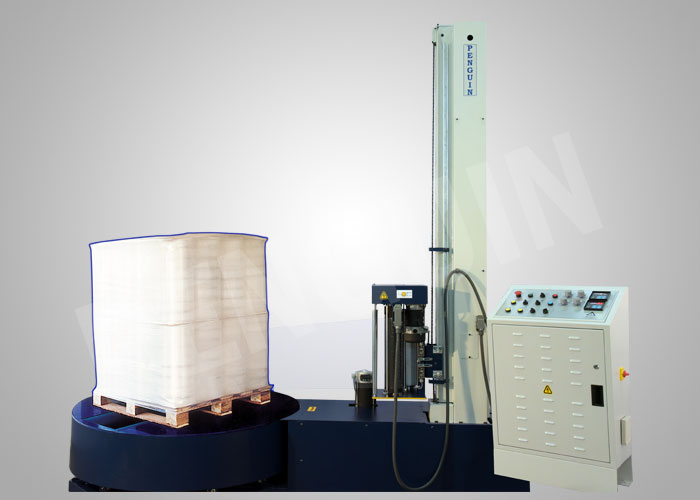

Reel Stretch Wrapping Machine

Model: REEL WRAPPER

DOWNLOAD LEAFLET

Penguin Reel wrapping machine packing paper reels in cocoon wrapping - On-site

Penguin Reel Wrapper is a machine specially designed for packing paper, film, foil and similar materials manufactured in reels. Axial Wrapping: The machine is designed to apply layers of film across the face diametrically and wrap them along the longitudinal axis. The longitudinally applied wraps are moved along the periphery with uniform overlap forming a cocoon type packing. This packing is completely Moisture & Dust proof and protects the product.

The Penguin Reel Wrapper is state-of-the-art machine having provision for wrapping reels over a wide range of diameters and lengths.

This Two-in-One machine can be instantaneously switched over from Reel Wrapping mode to normal pallet stretch wrapping mode by a selector switch. This machine can be easily integrated into conveyor lines.Read more...

Specifications

| CAPACITY | |

|---|---|

| Reels / Hour | 15 - 30 nos. |

| Pallet size | 1200 x 1200 mm |

| Pallet height | 2500 mm |

| Weight / Reel | 2000 kg |

| Reel diameter | 300 - 1000 mm |

| Reel width | 1200 mm |

| MACHINE | |

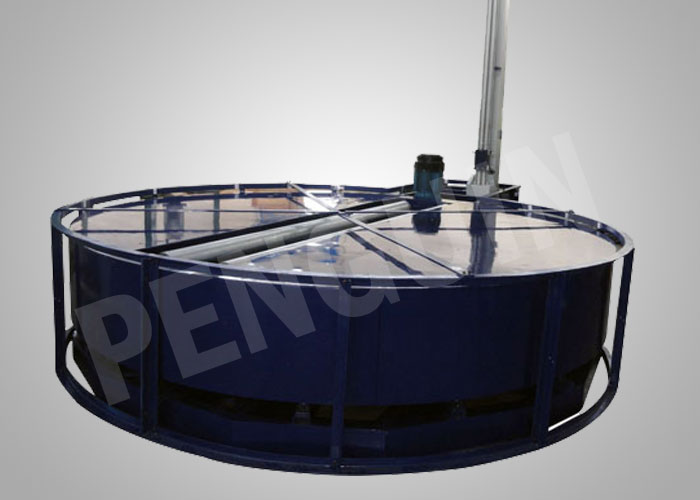

| Turn Table Diameter | 1600 mm |

| Turn table height (above GL) | 540 mm |

| Turn table speed | 1 - 10 rpm |

| Max.powered stretch | 300% |

| Installed power | 1.9 kW |

| Power supply | 220V, Single Phase, 50 Hz |

| FILM DETAILS | |

| Material | LLDPE Stretch film |

| Film width | 250 - 500mm |

| Film thickness - Range | 12 - 35µ |

| Film thickness - used | 23µ |

| Core diameter | 76 mm |

| Maximum film diameter | 250 mm |

- Ideal for materials produced in reel form with heavy weights and huge sizes like Paper, Newsprint, Non woven fabric, HDPE film roll

- Instant change from reel wrapper to pallet wrapper

- Dust free, moisture free cocoon type packing

- Pit mounting of machine ensures fast / controlled product flow

- Optional pneumatic reel ejection system

- Ease of integrating into conveyor lines

- Powered pre-stretch upto 300% stretch

- Counter gives Stretch % applied & quantity of Film consumed in each Reel / Pallet.

- Provision for wide range of reel diameters.

- Various levels of protection can be achieved by using flexible control of turn table and Reel speeds

- Completely automated machine.

- Low profile height of turn table for easy loading and unloading of reels

- Pit mounting of machine is possible so that loading & unloading of Reels is at Ground Level

- Applies pre-stretched film delivered from State-of-Art Powered Pre-Stretch Unit.

- Ideally suited for paper, film foil, tyrecord fabrics and similar materials produced in reel form

- Powered Pre-Stretch Unit

- Film stretch percentage can be easily adjusted to optimise film consumption and provide sufficient protection

Features of the machine

Productivity: 15 - 30 Reels / hour

Applications:

Rolls of paper, film, PP fabric, Denim fabric, HDPE film roll and foils

-

Instant change from Penguin Reel wrapper to Pallet Wrapper and vice versa

-

Penguin Reel wrapper with larger diameter turn tables. The above picture shows 3.5meter turn table

-

Paper reels wrapped in Reel Wrapper using wooden ramps for loading and unloading.

-

Reels shifted using a crab for storage or transport, after the reels are wrapped

-

Reels in weighing scale after being wrapped in dust free, moisture free wrapping

-

Wrapped paper reels are neatly arranged in a warehouse before despatch

-

Wrapped reels transported in a truck, lined up as secured packages

Gallery of Reel Stretch Wrapper

Read more on Penguin Reel Stretch Wrapping machine

Paper, Film, Foils, etc., in Reel form, cannot be easily wrapped with protective wrappers manually due to their heavy weight. Penguin Reel Wrapper, a “PACMACHINE” prestigious award winner, is suitable for the above products.

The machine uses 220V, 1-phase, 15 Amps power supply. It can stretch wrap Reels of various sizes in width & diameter, weighing even upto 1.5 tons, into a cocoon type packing. Whenever needed, it can be easily & instantaneously changed over from Reel wrapper to fully automatic Pallet Stretch wrapper. Electronic drives and microprocessor based cycle programmer cum monitor ensures uniform consumption of film for all the reels & pallets, once we preset. For the economical consumption of the stretch film, the inbuilt powered pre-stretch unit stretches the LLDPE stretchable cling film upto 300% before wrapping over the reel / pallet.

This method of packing gives the reel / pallet, protection from dust & moisture and ensures longer storage life while keeping the packing cost very much low, compared to packing them with Craft Paper / Hessain cloth etc. Industries like Paper Mills, Film Manufacturers, etc., can install this machine and save enormously in their packing costs, in labour costs, in time taken for packing, etc. This machine will pay back its cost very soon, because of these advantages.

Looking for an Adequate Solution for your Company?

Contact us today for free consultation or more information.

Contact Us© 2021 PENGUIN ENGINEERS