Hose Knitting Machine

DOWNLOAD LEAFLET

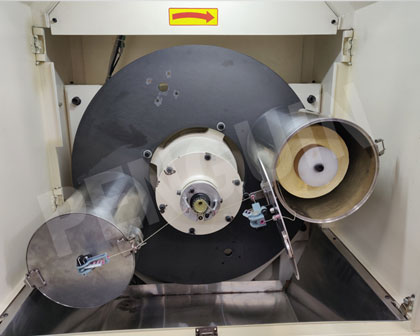

Hose Knitting Machine - Batch Process

Penguin hose knitting machine are world class machines for the knitted hose industry. Most of the radiator hose manufacturers in India and abroad use Penguin hose knitting machines and produce very high quality knitted hoses. A high speed version of the machine includes to the synchronized with the extruders, so as not to compromise the speed and production.

Hose Knitting is a recent concept in automobile radiator hose technology. Penguin Hose Knitting Machines are indigenously designed and Penguin are the only indigenous manufacturers of these machines in India and one among the very few manufacturers in the world.

This machine is characterised by high productivity, simplicity and excellent performance.

The hoses manufactured by this machine are far superior to conventionally wrapped hoses in strength, appearance and durability.

This machine is used for the manufacture of all types of bent hoses, curved hoses and hoses of various diameters used in automobiles.

Specifications

| Number of feeders | 2 to 4 (depending on size of the hose) | |

| Inner diameter of cylinder | 27 mm | |

| Maximum diameter of knitted hose | 10 to 100 mm | |

| Yarn package core diameter | 94 mm | |

| Maximum diameter of yarn packing | 210 mm | |

| Maximum height of spool | 260 mm | |

| Knitting module power | 2.25 kW; 3 Phase 440V | |

| Caterpillar power | 1.1 kW; 3 Phase 440V | |

| Interchangeable heads | Optional | |

| Type of stitch | Plain stitch | |

| Type of needle | Groz-Beckert make straight needle | |

| Number of needles | 10 to 40 | |

| Line speed | 1 to 3 m / min. | |

| Electronic control | Siemens make PLC &4" HMI | |

- Sturdily built tubular frame structure with enclosures

- Shaft mounted encoders and forced cooling fan for motors

- 2 to 4 feeders (bobbins) depending on size of the hose

- PLC & HMI touch screen for Electronic synchronisation of head & caterpillar motors for uniform pitch control

- Upto 3 kg different sizes of cone or cheese with upto 95 mm bore can be directly used

- Stainless Steel Yarn cover to avoid entanglement at high speed

- Interchangeable knitting heads

- Knitting heads can be designed from 10 mm to 100 mm hose ID

- Use of Economical and sturdy knitting needles

- Photo sensor stop motion for yarn cut

- Use of Economical and sturdy knitting needles

- Interchangeable knitting heads

- Line speed, Shift production indications and on-the-go pitch change through HMI

- Roof mounting light tower indication

- Different yarns like Aramid, Kevlar, Polyester etc can be used

KNITTING MACHINE

- Sturdily built rigid structure with enclosures

- 75 mm width timing belt with 6 mm thick linatex coating

- Bottom jaw adjustable by screw-rod for central line alignment

- Top jaw adjustable through stearing wheel

- Sturdy worm-reduction gearbox

- Two numbers of 90° gear boxes for jaw drive

- Tyre coupling for splined drive shaft

- Hose guide assembly at both the ends of caterpillar

CATERPILLAR

Looking for an Adequate Solution for your Company?

Contact us today for free consultation or more information.

Contact Us© 2021 PENGUIN ENGINEERS